Resin coating on the Welded Part

Occurrence of whiskers on the welded part is eliminated by applying UV resin coating onto the welded part of the lead terminal.

Patent No.: JP5329674B2

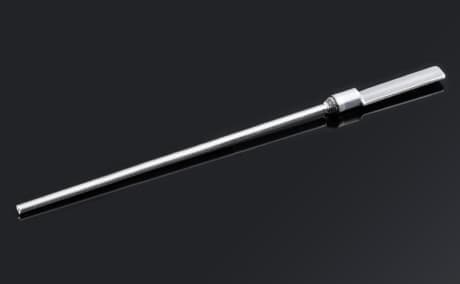

A whisker-like crystal with a thickness of a few µm and a length of a few mm called whisker may be occurred from the tin-plate of the lead terminal.

Whiskers, growing larger with time, would short-circuit the electronic circuit or wiring, to cause the electronic device to malfunction.

As general measures against whiskers, alkaline cleaning treatment is applied. Although this method can reduce whiskers to some extent, it cannot eliminate them completely.

Kohoku Kogyo established a unique method for applying UV resin coating to the welded part of the lead terminal and achieved complete elimination of whisker generation.

- Halogen-free resin

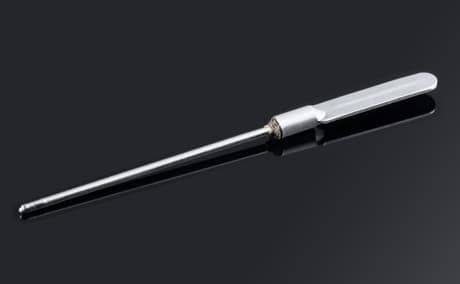

- Welded part with smooth shape

- No whisker generation during testing for 10,000 hours under an environment of 60ºC × 90%

- No whisker generation during testing for 10,000 temperature cycles between -50ºC and 150ºC

- No whisker generation during testing for 4,000 hours under a high temperature environment at 150ºC

Unprocessed (left), alkaline cleaning treatment (center), and resin-coated (right) welded parts. It is obvious that whereas whiskers are generated on the unprocessed and alkali-cleaned welded parts, no whisker is generated on the resin coating of the welded part.