Lead Terminals for Aluminum Electrolytic Capacitor

-

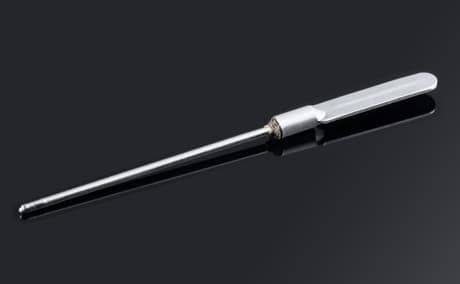

Standard Type

A standard type lead terminal.

-

Burr-free Type

Reduced burrs occurred during punching by improving the press process.

-

Edge-free Type

Reduced burrs occurred during punching by devising the die shape.

-

One-side Rib Type

The pressed part is shifted from the center, which contributes to the increase in the capacitance of aluminum electrolytic capacitors.

-

Round 4-corner Type

Corners of the pressed part is smoothened, which contributes to the capacitance expansion of aluminum electrolytic capacitors.

-

Vibration-resistant Type

Reduced damage to aluminum electrolytic capacitors due to vibration by unique shape design.

-

Front-back Discriminative Type

This lead terminal helps to distinguish front side from back side easier and prevents from malfunction of Aluminum electrolytic capacitor and electronic appliances by the breakage of Aluminum foil in capacitors caused by burrs of lead terminals.

-

Resin coating on the Welded Part

Reduced whiskers occurred from the welded part to zero by coating the welded part with resin.

-

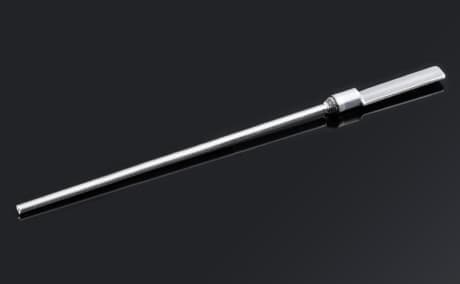

Resin Coating on the Round Bar Part

Reduced leak current occurred from the round bar part is reduced by coating the round bar part with resin.

-

Rounding processing

Damage during assembly of aluminum electrolytic capacitors is prevented by making the lead wire tip round.

-

Anodic Oxidation Processing

Insulation films are formed by anodizing the pressed part to reduce leak current from aluminum electrolytic capacitors.

-

Materials of Lead Terminals

Materials used for lead terminals are introduced here.